Distinguishing between screen printing and transfer printing

Fabric printing can be categorized into two main methods: traditional screen

printing and the emerging digital heat transfer printing. Below, we will discuss

the differences, advantages, and disadvantages of both techniques.

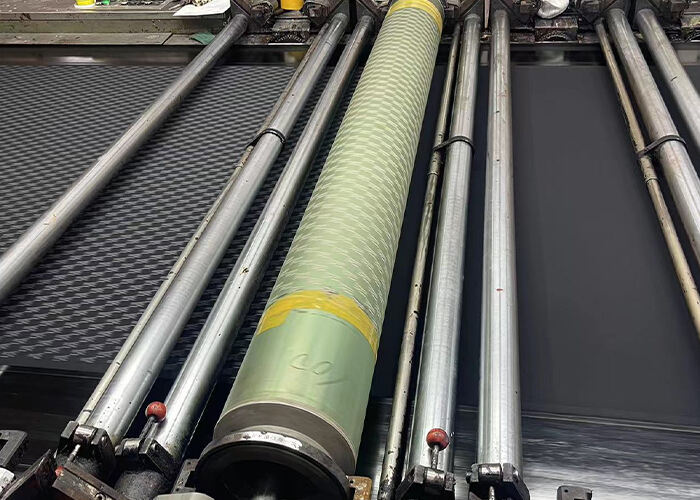

Screen Printing: Traditional screen printing involves applying ink onto

fabric through a patterned mesh screen. Its advantages include its ability to

work with various fabric types such as silk, cotton, blends, and polyester,

producing good results on both sides of the fabric. Another benefit is the soft

and fluffy hand feel achieved after washing.

However, traditional screen printing has clear drawbacks. The process

requires creating specific screens for each design which takes time and incurs

costs. Additionally, the color variety is limited by the number of screens used

in production which restricts vibrant patterns. Screen printing also results in

high fabric production waste requiring large order quantities suitable for mass

production of single patterns. Moreover, the need for washing in screen printing

generates considerable wastewater which could face further production

constraints due to increasingly strict global environmental regulations.

Digital Heat Transfer Printing: Digital heat transfer printing is an

innovative eco-friendly method where colors are precisely transferred from

printed paper to fabric fibers through high-temperature sublimation. This method

has no color or order quantity limitations offering precise colors, fast

production times and zero wastewater generation making it a mainstream

technology worldwide.

The downside of digital heat transfer printing is its relatively weak

penetration on the reverse side of fabrics and its current compatibility only

with polyester fabrics.

However, due to its increased environmental friendliness and

cost-effectiveness, along with rapid technological advancements, the current

limitations of digital heat transfer printing may also disappear in the near

future.